MSE Junior Katie Daehn talks about her summer research internship in Germany.

Having lived in Columbus my whole life, living in Germany for 12 weeks with a DAAD RISE scholarship was a hugechance for growth, both technically and personally. I left everything that was comfortable and familiar and headed on my own to Jena, Germany – a small town nestled between hilltops in the Eastern part of Germany. I spoke a little German from high school courses and had travelled in Germany with my dad and brother before, but living and working there introduced new cultural nuances that I never would have expected.

Keys are inserted into doors upside-down, checking out at the grocery store is a very rushed event, and “German bureaucracy” really exists. These nuances on top of meeting all new people, being immersed in a foreign language that I spoke worse than 2-year-olds, learning the ropes in a new lab, and taking a graduate-level polymer physics class in German, where I was regularly called on to answer questions, meant I had quite an adjustment time.

However, it was these hard times that made my time in Germany exponentially more meaningful. I embraced the experience, learned a ton, and felt alive. I met so many interesting people from around the world, saw a very influential history in a real way, and experienced some incredible moments traveling around Europe.

My internship involved researching and simulating the behavior of carbon fiber reinforced polymers (CFRP’s). Composites were an area of materials I knew little about going in, but they are light-weight with strengths comparable to metals, so conducting research in this growing and important area was definitely valuable to my career as a Materials Scientist.

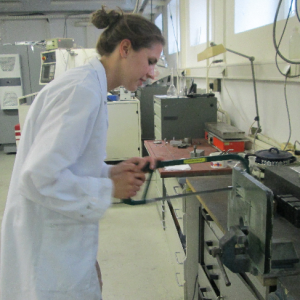

Sample preparation

I helped prepare CFRP plates, performed tensile tests, wrote a Matlab program to analyze the data, collected results on the elastic modulus, and used ANSYS to model our testing parameters. I gained experience in mechanical testing as well as in computer simulation and analysis.

My internship was very rewarding because I developed new skills, got experience with new equipment, worked with an international group of people, and saw first-hand how the German education system works and how research is conducted in a completely different lab.

It’s really hard for me to sum up everything my summer in Germany was to me, but it will always be precious. I really appreciate everything I learned in the lab, the work and consideration my advisor went into teaching me and always inviting me on coffee breaks, my fellow RISE students and our adventures – from sprinting to catch trains to long barbeques in the park. Though I’m more confused than ever about the world and my place within it, I’m filled with a new confidence to keep exploring. And the next time I’m overwhelmed by change and the unfamiliar, I’ll know that there are great people everywhere and I’ll find my way.

I am doing a materials internship this summer in Wichita, Kansas at Cessna Aircraft (now part of Textron Aviation), in the metals group of the Materials and Processes Engineering division. My internship requires me to inspect returned parts and parts from the production line, and to write condition reports on the pieces. I spend a lot of time in the lab, often getting dirty, and am consistently busy. I have been fortunate to be able to observe the entire production line, from raw material to finished airplane, for both Cessna and Beechcraft aircraft.

As for the rest of the summer, I also look forward to Engineering Fastener Training, Private Pilot Ground School, and a trip to San Francisco and Yosemite.